Spinning

Web Based Monitoring System is the measuring and recording of physical or electrical parameters over a period of time. Some applications require only a single measurement, while others may require multiple channels and multiple types of measurements. Web Based Monitoring System is available with various channel configurations: single-channel devices, multichannel devices, and modular devices with a mixture of measurement types. It can measure different types of signals and sensors including the following Production (Hanks, Kgs, Grams/Spindle, Meter/Minutes, Spindle Speed, TPI, TPM), Stoppage (Manual, Doff, Electrical, Mechanical), Line Voltage, Phase Voltage, Current, Kilo Watts, Frequency, Power Factor, KWH, Humidity and Temperature

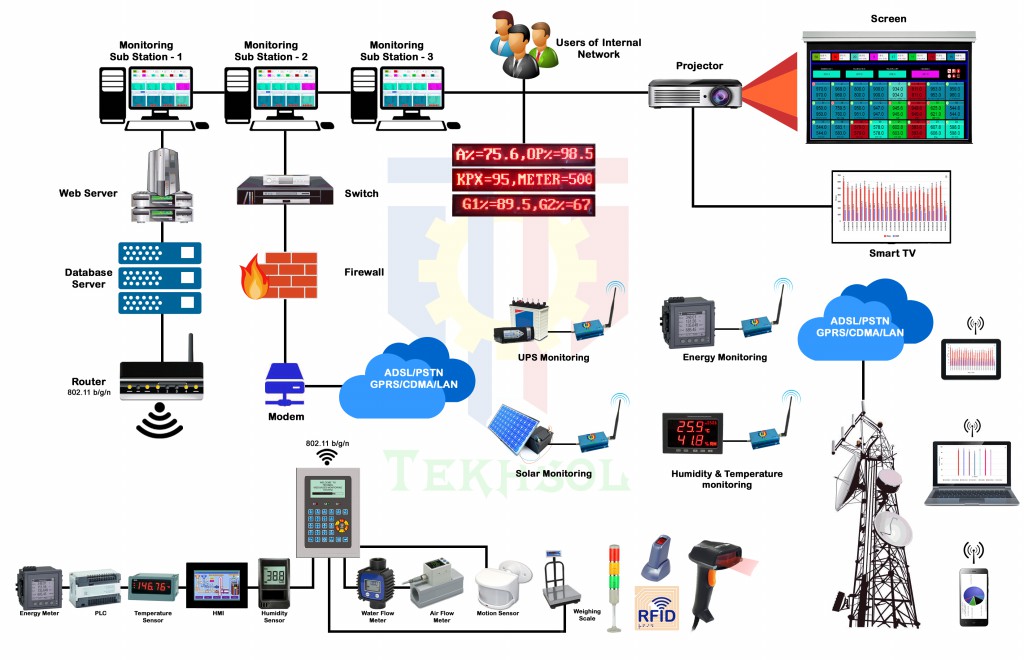

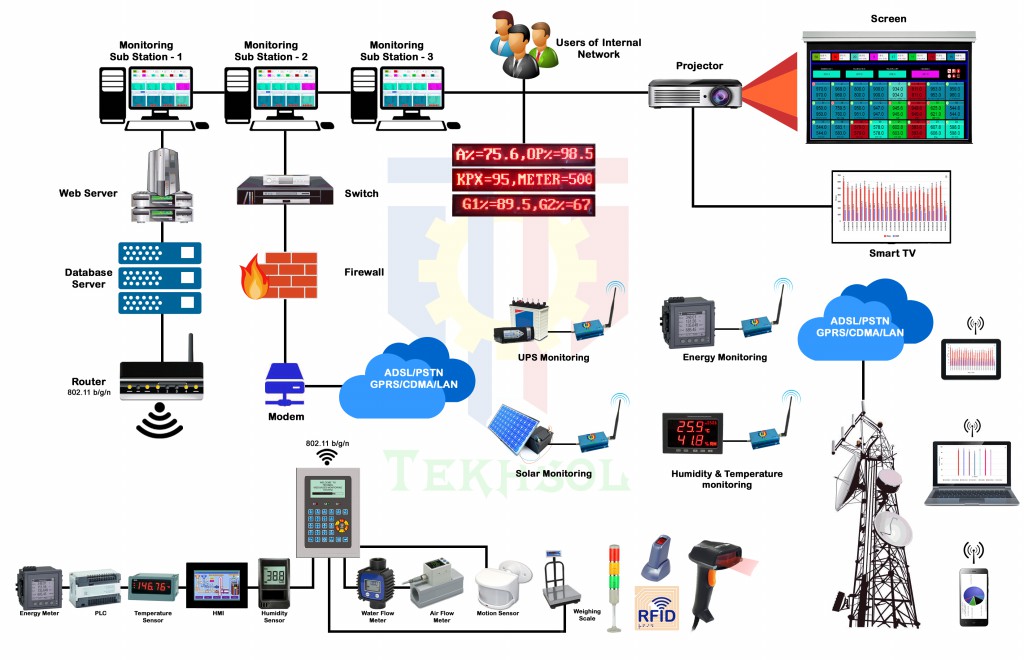

Block Diagram for Web Based Online Monitoring System

Block Diagram(Wireless) - Web Based Online Monitoring System for Spinning

Block Diagram(Wired) - Web Based Online Monitoring System for Spinning

Advantage of Web Based Monitoring System

This presents the following advantages over traditional stand-alone Web Based Monitoring System

| Production Details |

|

| Integrated All information about Machines at one Server |

|

|

| Clarify Weak Areas |

Machine Running Time |

|

|

| Actual Efficiency |

Production Efficiency |

|

|

| Installed Efficiency |

Utilization Efficiency |

|

|

| Instantaneous Spindle RPM and Average Spindle RPM |

Production in Hanks and Kgs |

|

|

| TPI |

TPM |

|

|

| Actual Grams/Spindle |

Expected Grams/Spindle |

|

|

| Meter/Minute |

Spindle Speed |

|

|

| Various Stop Time |

Doff Stop with Duration |

|

|

| Minutes/Doff |

Doff/Hour |

|

|

| Manual Stop with Duration |

Minutes/Manual |

|

|

| Manual/Hour |

Short Stops with Duration |

|

|

| Minutes/Short Stops |

Short Stops/Hour |

|

|

|

|

| Long Stops with Duration like Electrical, Mechanical and etc |

|

|

| Hour Wise Production(Hanks and Kgs) and Stop(Manual, Doff) Report with Analysis |

|

|

| Instant alerts for Order Status, Stoppages, Doff, etc.. |

|

|

| Production Planning and Order status Reports |

Automatic and Manual Doff |

|

|

| Doff Alerts & Reports |

Order Planning |

|

|

| Order Analysis |

|

|

|

| Automatic and Manual Employee Planning and Allocation |

Employee Analysis |

|

|

| Dashboard For Immediate Response |

Various Types Of Charts Like Line, Bar and Pie |

|

|

| Monitoring Screen For Production, Stoppage, Spindle RPM and Employee Details |

|

| Hour / Shift / Day wise /From To Production and Stoppage Reports |

|

| Monthwise Report For Production and Stoppage |

|

| Comparision Report For Any TWO Parameters |

|

| Units/Kgs |

|

| Usage Of Bar Code |

|

| Count Details |

Order Details |

Stop Code Details |

|

|

|

| Operator Details |

Technician Details |

Supervisor Details |

|

|

|

| Operator Group Details |

Technician Group Details |

Supervisor Group Details |

|

|

|

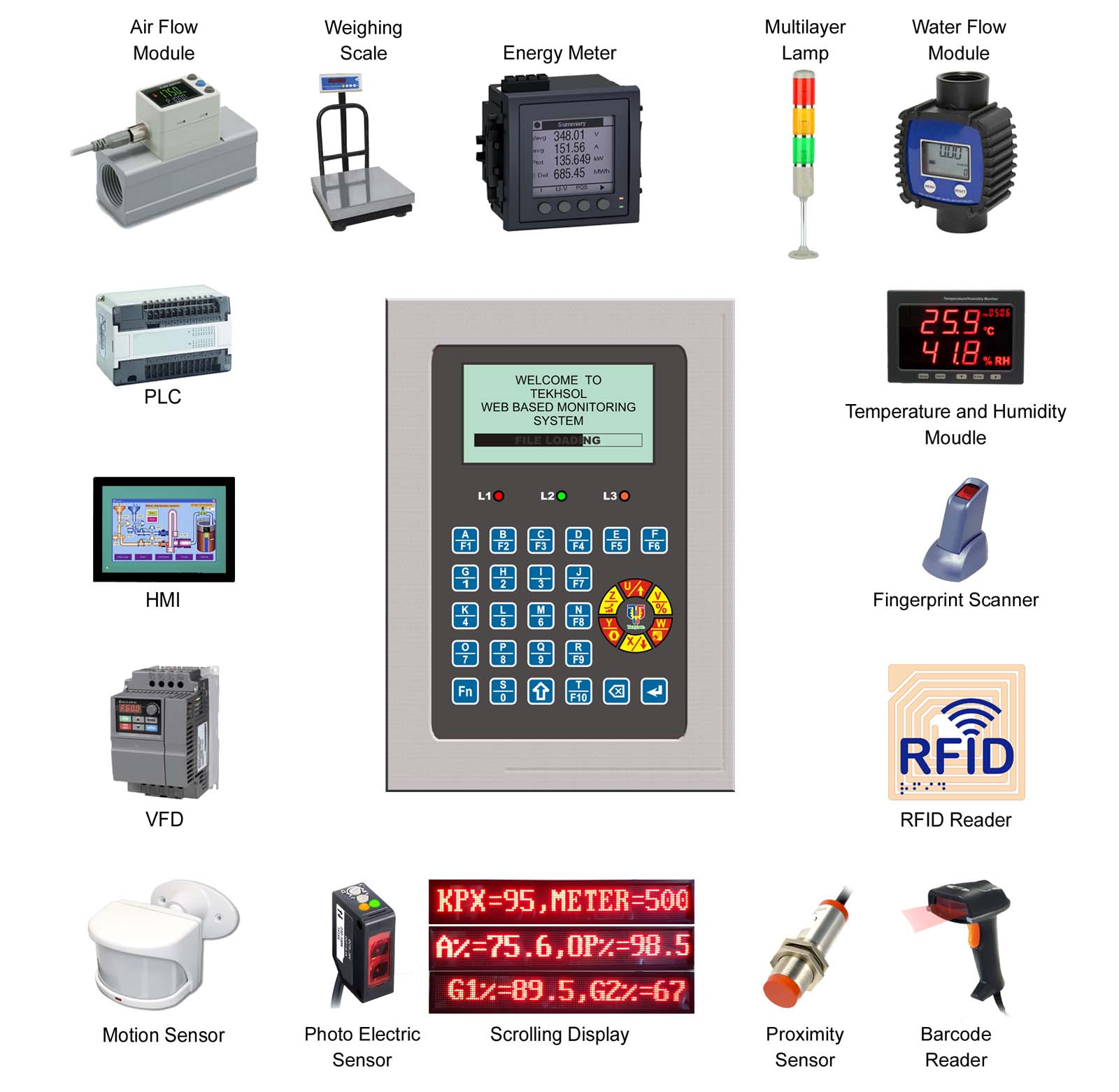

| Multilayer Lamp |

|

| To indicate Doff Stop |

Manual Stop |

|

|

| Energy Details |

|

| Line Voltage(R Phase,Y Phase, B Phase) |

|

|

| Phase Voltage (RY Phase,YB Phase,BR Phase) |

|

|

`| Current (R Phase,Y Phase, B Phase,Total) |

|

|

| Power Factor(R Phase,Y Phase, B Phase, Average - Instantaneous) |

|

|

| Watts (R Phase,Y Phase, B Phase ,Total) |

|

|

| Frequency |

|

|

| VAR (R Phase,Y Phase, B Phase ,Total) |

|

|

| VA (R Phase,Y Phase, B Phase ,Total) |

|

|

| KWH |

|

|

| Humidity |

|

| Minimum Humidity Value(Rh) |

Maximum Humidity Value(Rh) |

Live Humidity Value(Rh) |

|

|

|

| Temperature |

|

| Minimum Temperature Value(Celsius) |

Maximum Temperature Value(Celsius) |

Live Temperature Value(Celsius) |

|

|

|

Features

- Web Based Monitoring System is a microprocessor based real time production monitoring system. It acquires data directly from the machines by means of signals. Web Based Monitoring automates the production and stoppages data directly to computer for spinning departments.

- Doff, Manual and Other stoppages are directly recorded to computer as Doff, Manual and Other stoppages. This greatly helps the management to control the stoppage variation and thereby to improve productivity.

- For every stoppage, Web Based Monitoring System records the start time and end time of the stoppage against the machine, shift and date. The user is allowed to change a suitable reason for such a stoppage from the existing stop reasons at the end of a shift or latter on. Also, the user is allowed to eliminate certain type of stoppages for which the duration is less than out of production time so and which are not considered while production calculation. This greatly improve the accuracy in production calculation.

- Web Based Monitoring System Production information with respect to Spindle RPM, Production, Efficiency and Stoppages are available to the user up to the minute.

- User friendly Web based Software. User can monitor the industry anywhere from the world through Internet. Integrated information of all Machines at one place.

Monitoring Screen to show current month, Previous Shift, Previous Day and current shift status with easily understandable user friendly GUI.

- Dash board for cumulative display of collected data in a single page. Running and Stoppage machines with their percentage. Efficiency wise machines counting with percentage. Instantaneous and Running shift efficiency and production data in the dash board view.

- Various Reports on Production, Stoppage & Efficiency based on selected criteria.

- Each detailed report will say the working machine's for the day performance along with the up to date performance is the special quality of Web Based Monitoring software.

- Performance of any Machine, Count, Employee or Group can be analyzed at any point of time for any chosen period of working. For any chosen period can be analyzed.

- Count Changes for completed shifts with high level authentication.

- Real time and past data comparison on Machine, Count, Operator, Technician, Supervisor, Operator Group, Technician Group, Supervisor Group, Buyer, Order etc.,.

- Periodical Break analysis and Efficiency Graphs to improve Production and Quality.

- Production Planning and Order status Reports.

- Projected Production information to improve current shift Production & Efficiency.

- Our Web Based Monitoring software allows the user to input worker's planning and existing men allocation and details.

- Total working performance of Mills for last shift would be immediately available to the current shift Executives.

- Total working performance of the Mills for a day would be immediately available after the end of the day to the Top Executives. Month end Production report and stoppages analysis reports are immediately available after the month end without any manual preparation.

- There is no manual calculation and integration is required at any point of time for any kind of report.

- As the production parameters are directly recorded from the machines, the special efforts of the system can be realized and the time reduction in the clerical work can be understood.

- Web Based Monitoring System is also allows direct input for production and other working details. Which are not censored by Web Based Monitoring System. This helps the management to have total production monitoring through computer. The management can realize the completeness in computerizing the production activity.

- In most of the reports Mills standard has been compared.

- More than 200 different kinds of reports are available. Each of these reports are carefully designed and are very meaningful to control the production routines in all respects.

- Graphical representation of data with respect to productivity and stoppage are also available for quick and easy understanding of the Mills performance.

Additional Features

- ERP Interface.

- SMS Alerts (Optional).

- Provision to send reports by e-mail automatically (Optional).

- Provision to connect big LED / LCD screens (Optional).

- Provision to show Running Display.

Sample Screen Shots

Time To Next Doff

Time To Next Doff

View more